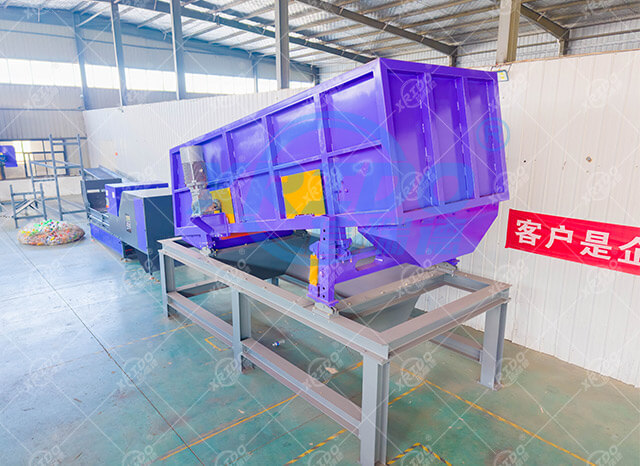

Working principle

The heavy ballistic separator is sorted material by differents size/ shape/ density machine. its tough sorting used to construction waste, kitchen waste after squeezing water, paper recycling industry etc.The bouncing screen drives the sieve plate to move up and down through the eccentric shaft (crank gear, etc.), so that the solid waste on the sieve plate is shaken into heavy, rolling 3D material parts (such as plastic bottles, wood, cans, etc.) and light, The flat 2D material part (film, paper, cardboard) and the under-screen material part (sand, food residue) are convenient for subsequent processing.

Appliance

According to the characteristics of the above equipment and the complex characteristics of solid waste, it is mainly used in the domestic construction and decoration waste front-end pre-sorting, domestic waste incineration slag light material, and some industrial waste sorting systems.

Household waste

Construction Waste

Bulky waste

Landfill Stale Waste

Under the driving motor, the bouncing sorting screen is connected with the support seat and the sieve plate to form a parallel four-bar mechanism through the active and passive transmission mechanism composed of the driving shaft, the driven shaft, and the eccentric wheel (crankshaft, chain and other transmission devices), and the sieve plate produces Similar to the reciprocating circular motion of bouncing, the materials input from the feed port are separated into three types, 3D materials with large particle size and good rebound effect, heavy and rolling, and under-screen materials with small particle size and poor rebound effect , flat and light 2D materials with large particle size and poor rebound effect are received by three discharge hoppers respectively.

According to the different climbing ability and bouncing performance of different materials, it will be affected by the tilt angle during the screening process. Therefore, the angle between the box and the sieve plate can be adjusted as a whole through the hydraulic jacking system to adjust the bouncing lifting angle of the sorted materials.

Sorting Material

Parameters

Capacity and detail customized by customer.

| Model | Motor Power(kw) | Number of screening plates(PCS) | Weight(t) | Capacity(t/h) |

| RDT-4 | 7.5 |

4 |

7.5 |

≤20 |

| RDT-6 | 11 | 6 | 10 | ≤30 |

| RDT-8 | 15 | 8 | 12 | ≤40 |