Working principle

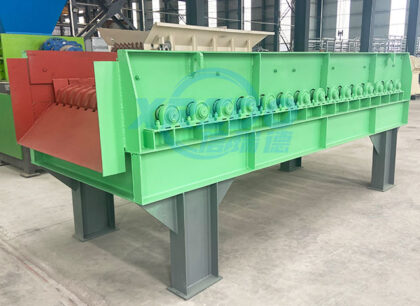

Double shaft shredder is one kind of low speed, high torque tearing machine, its widely used to waste metal, bulky waste or MSW, industrial waste and domestic scrap. through bit to reduce the size of material, improve density to save the transportation charge. The reducer and rotor connection takes Germany type meets DIN5480 standard.

Appliance

Its mainly used to the industrial waste, domestic waste, scrap metal, medical waste, solid waste etc.

Household waste

Construction Waste

Bulky waste

Landfill Stale Waste

Advantage

Parameters

| Model | Power (KW) | Rotating speed (r/min) | Dimensions L/W/H(mm) | Crushing cavity size C/D(mm) | Diameter of knife body (mm) |

| XR-56 | 15+15 | 6-20 | 2800×1300×1850 | 600×500 | 220 |

| XR-58 | 18.5+18.5 | 6-20 | 3000×1300×1850 | 800×500 | 220 |

| XR-710 | 30+30 | 6-20 | 3300×1900×2200 | 1000×700 | 320 |

| XR-812 | 37+37 | 6-20 | 3600×2000×2200 | 1200×800 | 400 |

| XR-815 | 45+45 | 6-20 | 4180×2100×2400 | 1500×850 | 450 |

| XR-918 | 75+75 | 6-20 | 5800×2400×3300 | 1800×900 | 500 |

| XR-1020 | 90+90 | 6-20 | 6400×2700×3500 | 2000×1000 | 600 |

| XR-1522 | 110+110 | 6-20 | 7800×3200×3800 | 2200×1500 | 800 |