Working principle

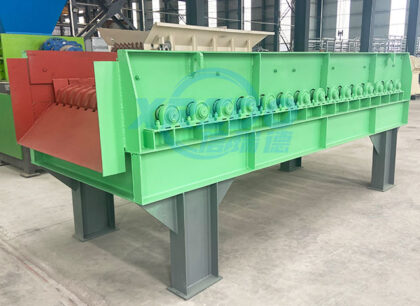

The manual sorting platform consists of belt conveyor, platform,silo,safety protection device,light steel workshop (optional) etc, material is along with material to the sorting platform. Such as plastic, paper, fabric, battery, glass etc will be sorted and put to different silos by workers. The left material will go next step , the belt conveyor takes VFD and places at middle part. There is a silo for every station at both sides of sorting platform.

The manual sorting platform is mainly used in the parts of the waste treatment line that cannot be sorted by machinery. It is mainly used for manual sorting of large disturbances before rolling screens and manual sorting of resource utilization after fan winnowing.

At present, there are several main ways of garbage classification in our country: manual sorting, mechanical physical screening, and intelligent garbage sorting equipment sorting. The working modes and technical principles of manual sorting and mechanical physical screening are relatively mature. Manual sorting platforms of different specifications such as 4 stations, 6 stations, and 8 stations can be customized as required.

Appliance

It is mainly used for manual sorting of large disturbances before rolling screens and manual sorting of resource utilization after fan winnowing.

Household waste

Construction Waste

Bulky waste

Landfill Stale Waste

Advantage

Parameters

Capacity and detail customized by customer.