Garbage sorting system

The decoration waste sorting machine can sort waste cloth, plastic bags and other sundries in the decoration waste recycling aggregate, and can also clear out large and medium-sized wooden blocks and plastic stool waste. After two screenings, the impurity separation rate reached 98%. Among them, concrete and waste rock are used to produce coarse and fine aggregates, which can be used to produce concrete and mortar of corresponding strength levels or to prepare building materials such as blocks, wall panels, and floor tiles.

After adding cured material to coarse and fine aggregate, it can also be used for the base course of road pavement. Waste bricks and tiles are used to produce aggregates, which can be used to produce recycled bricks, blocks, wall panels, floor tiles and other building materials. The muck can be used for road construction, pile filling, foundation, etc. Abandoned wood construction waste and undamaged wood can be directly reused in other places, and severely damaged wood components can be used as raw materials for recycled wood to make cardboard or paper.

Materials suitable for the sorting and recycling machines

Its mainly used to the household waste, industrial waste, construction waste, decoration waste, and stale waste etc.

Household waste

Construction Waste

Bulky waste

Landfill Stale Waste

Introduction of domestic waste sorting system

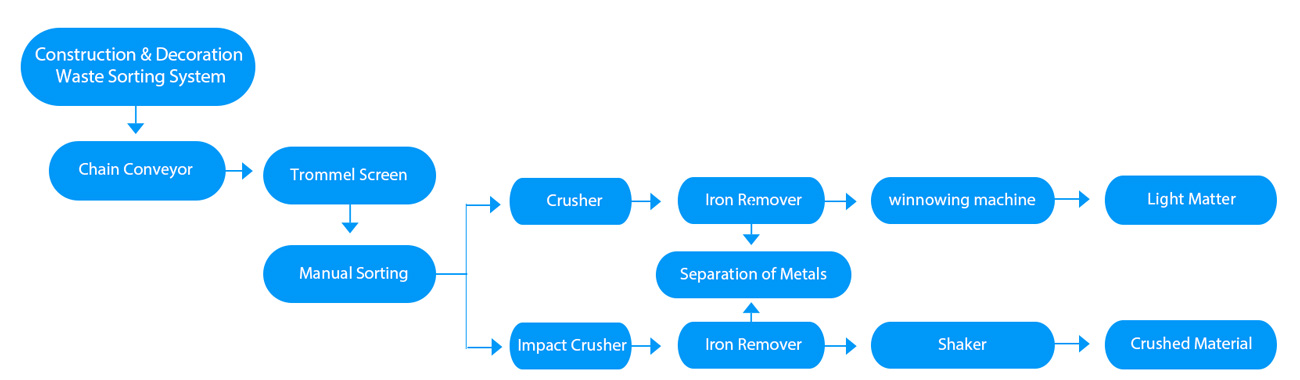

Construction and decoration waste sorting equipment is through a series of processes such as conveyor, winnowing machine, drum screen, magnetic vortex sorting machine, winnowing, dust collection and gas treatment. Separate copper, aluminum and non-ferrous metals, iron and magnetic materials, plastic rubber, stainless steel, heavy sand and gravel, organic matter and sundries, and large clothes in the original materials. The purity can reach about 98%. The process is fully automated from feeding to sorting, with a daily processing capacity of 300-500 tons, requiring only a small amount of manual operation.

There are different models of construction waste disposal machines, including XRD-100, XRD-200, XRD-400. Their production capacity ranges from 100 tons to 400 tons per day, meeting the different needs of customers.

Garbage sorting equipment workflow

video

C&D Waste Sorting and Recycling Line

The production line can be customized based on actual materials and processing volume.