Garbage sorting system

Stale garbage is mainly due to the fact that after years of microbial decomposition, the fermentation water is relatively large, which makes the content of organic matter extremely low. The stale garbage needs to be dug out before screening, and part of the separated combustibles will be used for garbage incineration. A part is composted and landfilled.

Materials suitable for the sorting and recycling machines

Its mainly used to the household waste, industrial waste, construction waste, decoration waste, and stale waste etc.

Household waste

Construction Waste

Bulky waste

Landfill Stale Waste

Introduction of waste sorting system

There are a lot of construction waste in stale garbage, and there are also a lot of oversized garbage. In order to automatically sort out the oversized items, in order to reduce the cost of manual sorting.

The stale domestic waste in the landfill is sorted into:

The sorting purity of the above garbage can reach more than 85%, and the sorting purity of film plastics can reach more than 90%, laying a solid foundation for the "recycling and industrialization" of waste treatment in the next process.

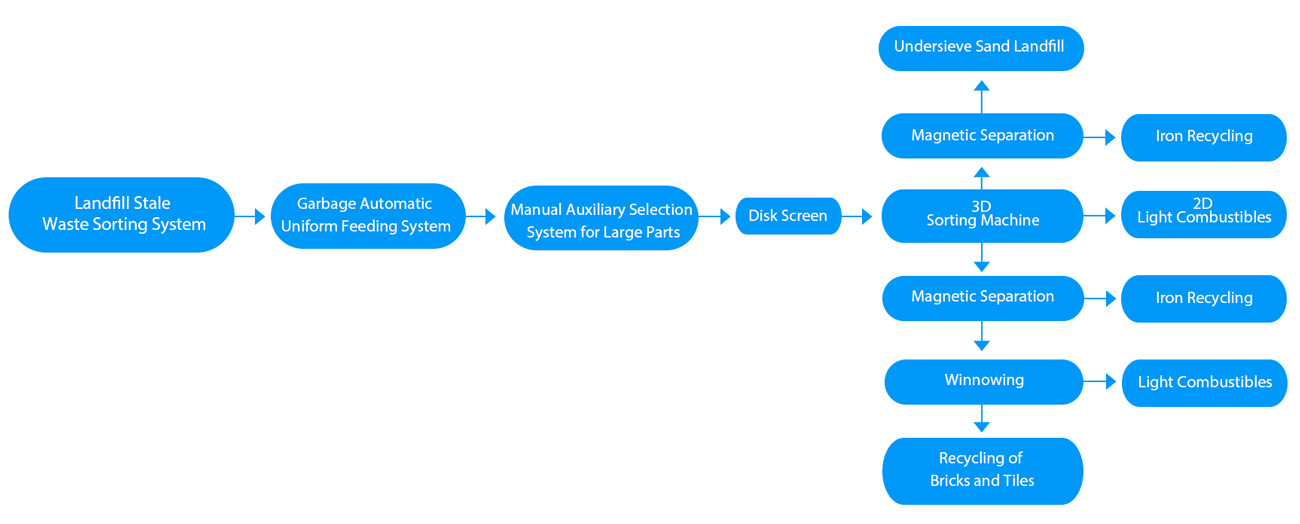

Garbage sorting equipment workflow

Video

The production line can be customized based on actual materials and processing volume.