Our Waste To Biomass/RDF/SRF/TDF Briquette Plant

The Solid Waste To Biomass/RDF/SRF/TDF Briquette Plant can be customized according to your actual situation and materials.

MSW to RDF briquette Plant

Industrial Waste to RDF briquette Plant

Biomass pellet/briquette Plant

Waste Tire Disposal System

Materials Suitable for Biomass/RDF/SRF/TDF Briquetting System:

Its mainly used to the Solid Waste, Municipal waste, Industrial Waste, Agriculture Waste, Forest Waste, MSW Waste, Wood Waste, Texitile Waste, Leather Waste, Biomass, etc.

Domestic Waste

Industrial Solid Waste

Biomass

Waste Tires

Paper Mill Waste

Waste Textiles, Leather

Landfill Stale Waste

Bulky Waste

Turning Solid Waste To Energy Fuel Plant

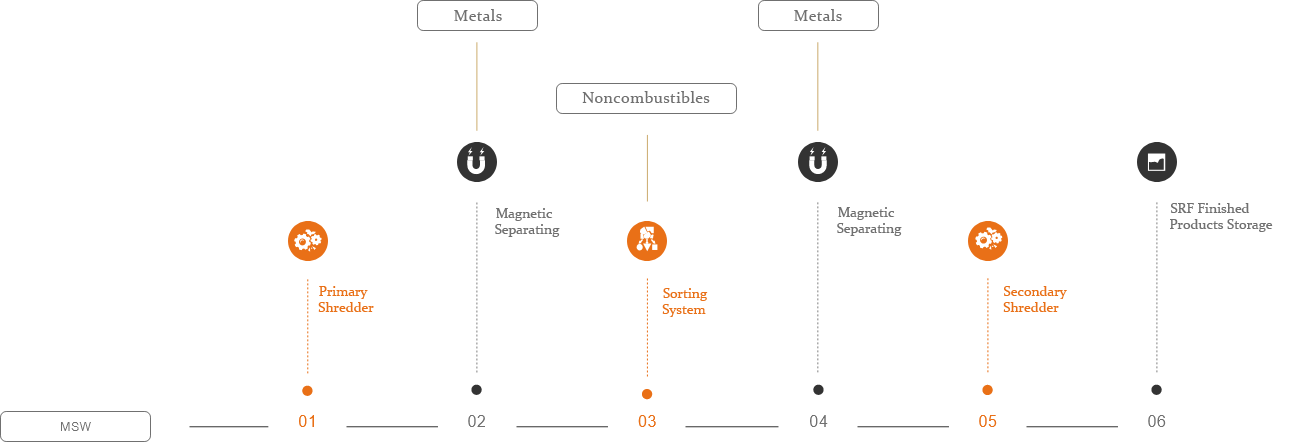

Refused derived fuel ( RDF ) technology refers to the process of crushing, sorting, magnetic separation, re-crushing, drying, briquetting, and processing the combustible waste into solid recovered fuel ( SRF ) briquettes. The application of RDF technology reduces environmental pollution greatly. It is a safe treatment for city waste.

We are a professional briquetting and pelleting production line manufacturer, which is committed to designing more efficient and reasonable plant processes and developing more energy-saving and environmentally friendly briquetting & pelletizing machines. We firmly believe that waste is a misplaced resource, and devote ourselves to helping our customers reduce the cost of waste disposal, and obtain additional treasure from waste.

Energy Fuel Finished Product Display:

Video

Waste To RDF SRF Briquette Plant

The production line can be customized based on actual materials and processing volume.

Introduction of Waste To Biomass/RDF/SRF/TDF Briquette Plant

One ton of refuse-derived fuel can replace 715 kg of coal, 590 kg of petroleum coke, and 500 kg of oil fuel. In China, RDF/SRF briquettes have been used in high fuel demand industries such as power plants, gasification power generation, and cement plants for a long time. Against the background global energy shortage, promoting the development of RDF briquettes can alleviate the dependence on traditional fossil fuels. It is of great significance to reducing carbon dioxide and protecting our environment.